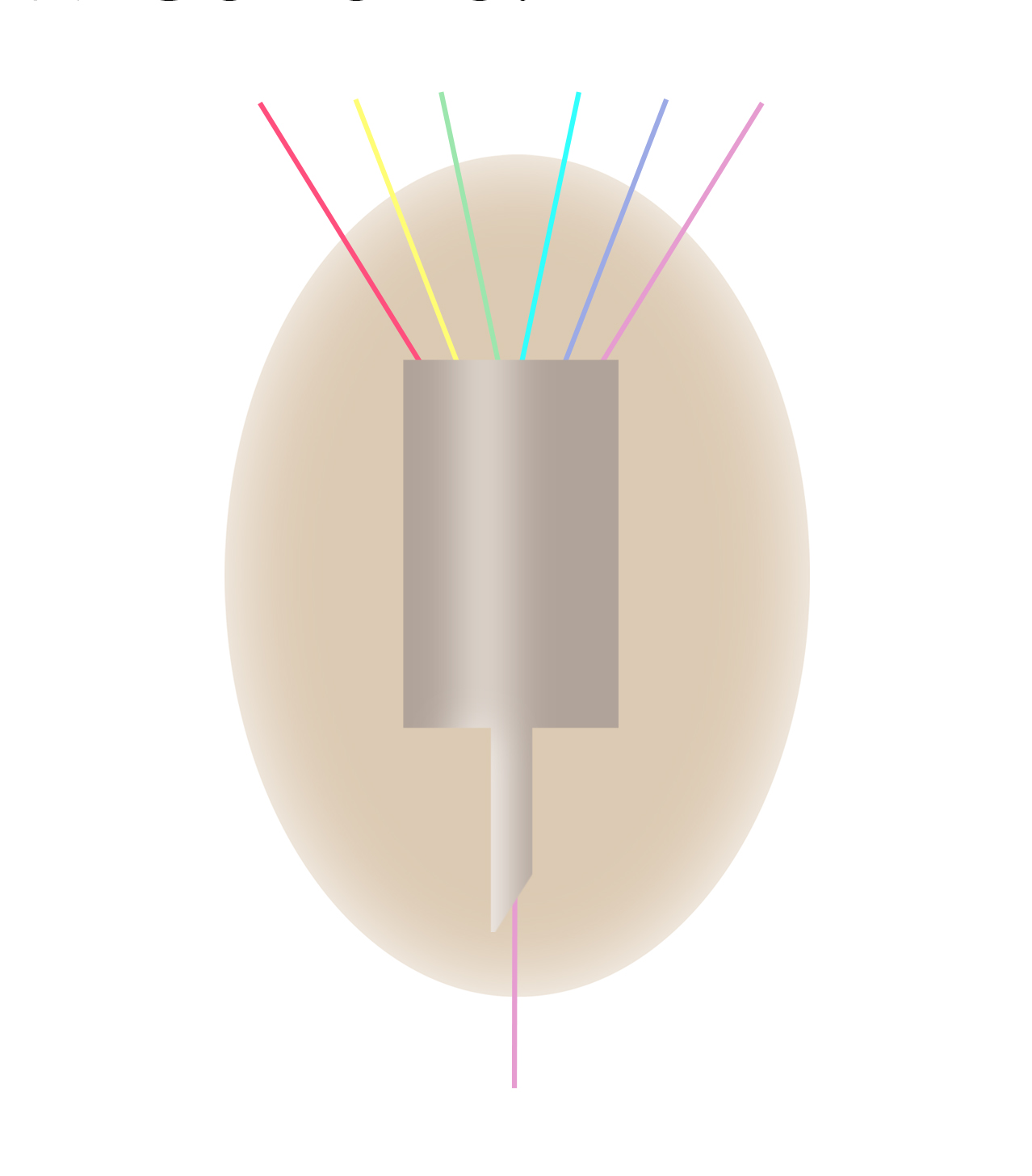

Each needle holds six yarn colors. As the backing is shifted under the needle each color is sent through at 1/16 of a second. This machine can electronically change: Stitch rate, gauge, product width, art repeat, cut or loop pile, up to 6 colors, and natural or synthetic yarns.